We are specialized in the sphere of manufacturing a wide ringe of wooden pallets, available in various sizes, shapes and dimensions and can also be customized as per the specifications, provided by our clients.

Wooden Packaging

Why to choose wooden packaging ?

Wooden packaging constitutes 80% of the packaging of major goods world over, as most of the pallets are made from wood. Wood is easily convertible, environment friendly, not energy intensive Wooden packaging material are of softwood, hardwood or the mixture of both. Each type of wood has their own advantage but generally wood is inexpensive, durable and can be recycled.

Wooden Pallets

Wooden Boxes

We offer wide range of wooden boxes sturdy designs which gives an exceptional strength. While the best quality wood ensures reliability, these custom wooden boxes are best as they provide full Protection to goods during transit.

Wooden Crates

Wooden crates offers extra safety for all your priced or valuables for extra protection. It is often made from the high grade woods, and finely finished with water resistance.

Contract Packaging

We provide contract packaging services which is hassle free and affordable. All contract packaging services are done in a clean, orderly facility staffed by logistics experts.

Packaging Materials

Manufacturers and suppliers of Packing Materials like Corrugated Box, Courier Bags, Bubble Films, Stretch Films, Adhesive Tapes, Strap Rolls and Packaging Accessories.

Domestic & export Packaging

We are service providers of Domestic & Export Packaging. The right packaging provided by sus can make the difference between damaged goods and lost revenue or goods arriving safely and efficiently for maximum profit.

Jungle & Pine Wood Cut Sizes

We supply all types of Jungle Wood and Pine Wood cut sizes as per the requirement.

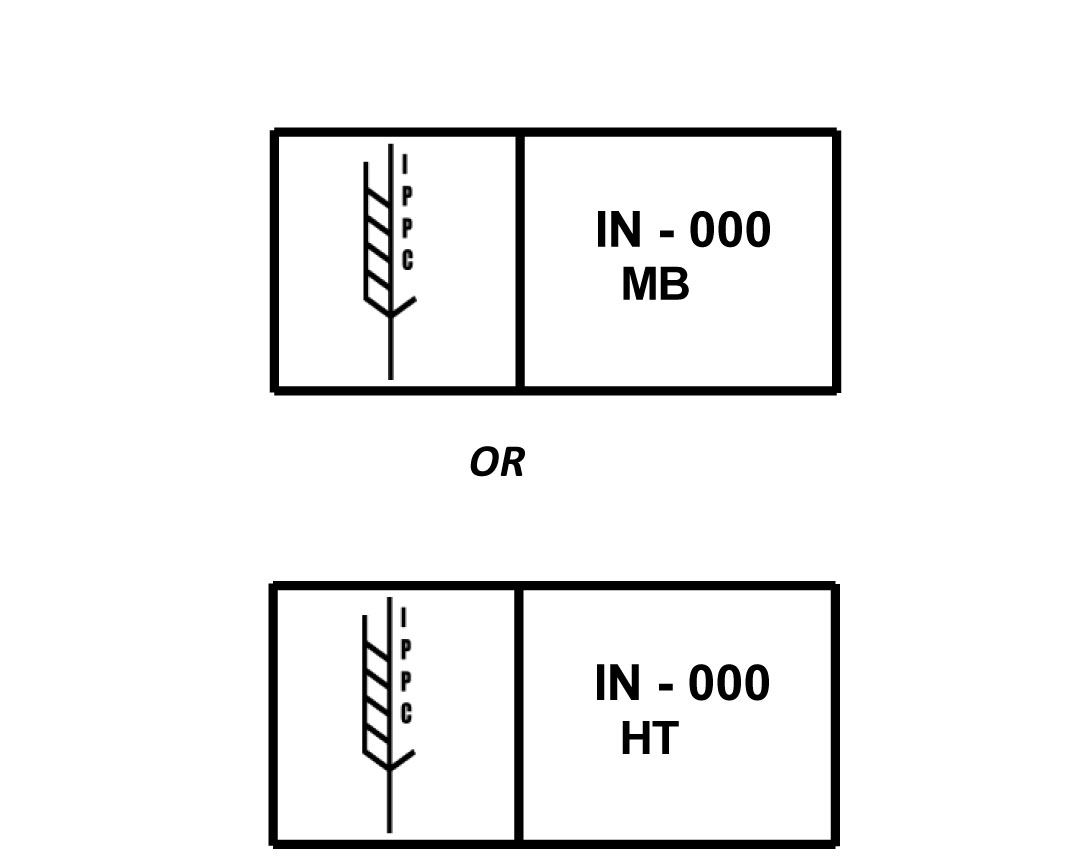

Heat Treatment & Fumigation (ISPM15)

Heat treatment (HT) works by maintaining a specific time/temperature curve so that the centre of the treated wood remains at a minimum temperature of 56°C for a minimum period of 30 minutes. This process takes place in chambers designed especially for this purpose where the temperature of the wood is measured using sensors on different pieces of wood in different parts of the chamber. Hot air is circulated around the chambers in order to keep the air at a constant temperature. This system eradicates any insects living inside the wood that could cause an outbreak of disease or plague.

Designed and Developed by: G WEB SOLUTION